Planet IMG-2100T

€ 139,00 (ex. VAT)

€ 168,19 (incl. VAT)

- Industrial Modbus Gateway

- 1-port RS232/422/485

- 1-port RJ45 10/100BASE-TX

- DIN-rail and wall-mountable

- 9-48VDC / 24V AC power feed

4 in stock

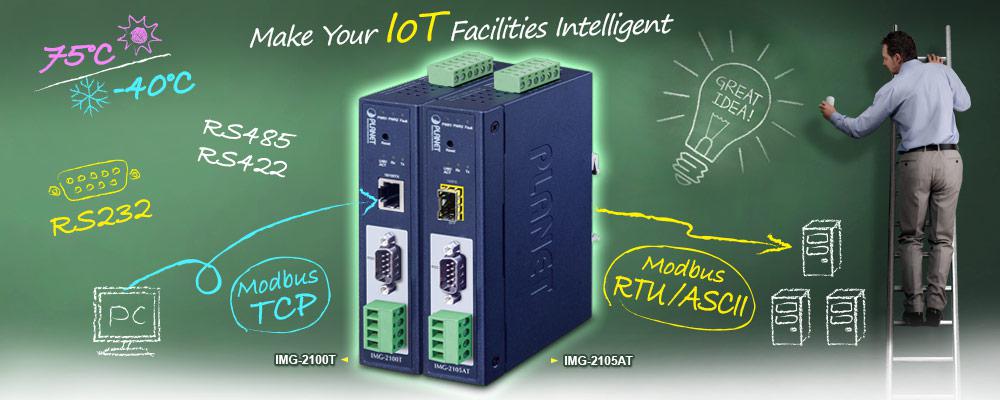

Standard Industrial Modbus TCP/RTU/ASCII Network Integration

PLANET has added the Industrial Modbus TCP/IP Protocol to its easily-integrated industrial management level products that come with SCADA/HMI system and other data acquisition systems on factory floors. Moreover, the industrial IT SNMP network is upgraded to the Industrial automation Modbus TCP/IP network. PLANET industrial management level products with the Modbus TCP/IP Protocol offer flexible network connectivity solutions for the industrial automation environment.

To complete the industrial automation environment application solution, PLANET has announced a first industrial level 1-port RS232/422/485 Modbus Gateway, IMG-2100T, a bridge that converts between Modbus TCP/IP Protocol and Modbus RTU/ASCII Protocol. It features a wide operating temperature range from -40 to 75 degrees C and a compact but rugged IP30 metal housing.

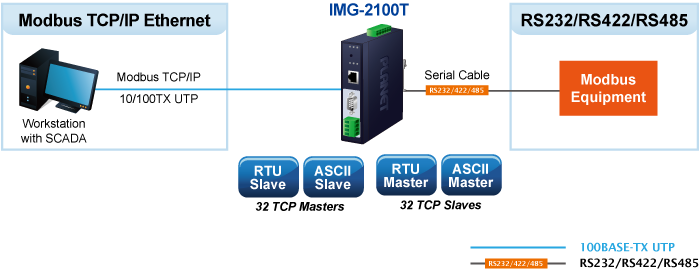

A Conversion Bridge for Flexible Network Deployment

The IMG-2100T can be a conversion bridge between the equipment with the Modbus RTU/ASCII Protocol and the administrator workstations that run the Modbus TCP/IP Protocol. The RS232/422/485 serial interface of the IMG-2100T provides the Modbus RTU/ASCII operation mode and various baud rate options to meet the demand of integration between the Modbus TCP/IP Protocol, Modbus RTU Master/Slave Protocol and Modbus ASCII Master/Slave Protocol.

The advantage of having the IMG-2100T is to assist users to build an industrial environment between the Modbus TCP/IP Protocol and the Modbus RTU/ASCII Protocol easily, thus offering an application solution to the industrial control equipment without Ethernet ports and the industrial control equipment can only control through an industrial PC workstation or industrial control panel.

In addition, the effective integration solution of Modbus Ethernet devices, Modbus serial equipment or multi Modbus master / slave in an industrial hybrid network brings the following:

- Master mode supports up to 32 TCP slave connection requests

- Slave mode supports up to 32 TCP master connections

Remote Management

The IMG-2100T makes the connected industrial Modbus RTU/ASCII equipment become IP-based facilities and is able to connect to the Modbus TCP/IP network via its RS232/422/485 serial interface and 10/100BASE-TX RJ45 Ethernet port. It provides a remote web management and telnet Interface for efficient remote network management. The IMG-2100T also provides PLANET Modbus Gateway utility tool and supports PLANET Smart Discovery utility to help network administrator to easily get the current IP subnet address information or change the IP subnet address setting of the IMG-2100T.

Modbus Serial Port State Monitoring

The IMG-2100T shows the details of the total bytes transmitted and received on the RS232/422/485 serial interface, and the detailed total number of frames transmitted and received on the remote web/telnet management interface. This function allows network administrator to check the status and statistics of the IMG-2100T via the single RS232/422/485 serial interface.

Stable Performance in Hardened Environment Design

The IMG-2100T provides a high level of immunity against electromagnetic interference and heavy electrical surges which are usually found on plant floors or in curb-side traffic control cabinets. Its operating temperature ranging from -40 to 75 degrees C allows the IMG-2100T to be placed in almost any difficult environment.

The IMG-2100T is equipped with a compact IP30-rated metal case that allows wall mounting for efficient use of cabinet space. The IMG-2100T also provides an integrated power supply source with wide-ranging voltages (9 to 48V DC / 24V AC) ideally suitable for worldwide operation with high availability applications.

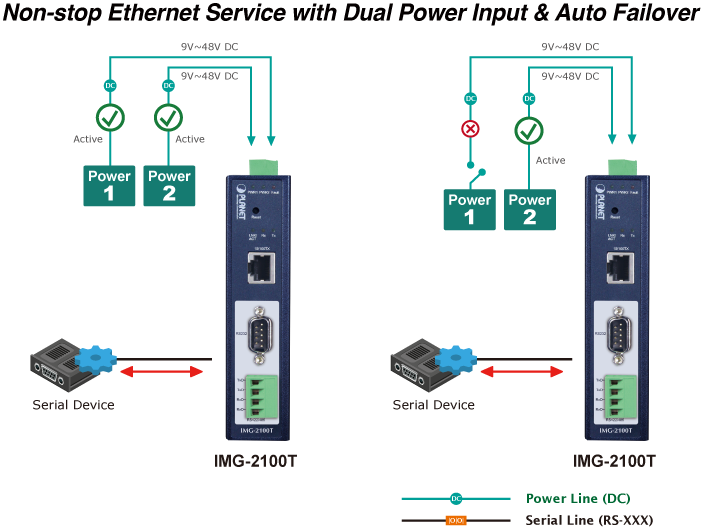

Dual Power Input for High Availability Network System

The IMG-2100T features a strong dual power input system with wide-ranging voltages (9V~48V DC / 24V AC) incorporated into customer’s automation network to enhance system reliability and uptime. In the example below, when Power Supply 1 fails to work, the hardware failover function will be activated automatically to keep powering the IMG-2100T via Power Supply 2 without any break of operation.

Related products

Industrial Ethernet

– DC power adapter

– Din-rail mounting suitable

– Power 40Watt

– Output voltage: 48Volt DC

€ 24,86 (ex. VAT)

€ 30,08 (incl. VAT)

Industrial Media Converter

– Industrial Media Converter

– 2 port 10/100/1000T

– 2 port 100/1000/2500X SFP

– Temp. range -40 ~ +75 degrees

– IP30 DinRail case

€ 149,00 (ex. VAT)

€ 180,29 (incl. VAT)

Industrial Media Converter

– Industrial Media Converter

– 100/1000X to 10/100/1000T

– -45 – +75 degrees Celcius

– 9 – 48V DC Terminal Block

– Din-rail and Wall Mountable

€ 79,95 (ex. VAT)

€ 96,74 (incl. VAT)

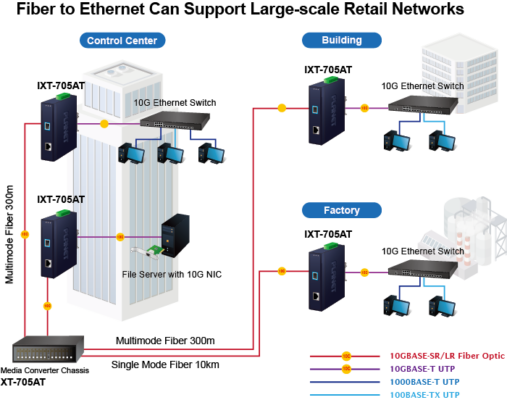

Industrial Media Converter

- Industriële media converter

- 10GBASE-X SFP+

- 10G/5G/2.5G/1G/100M

- -40 ~75 graden C.

- Redundant AC/DC

Industrial Media Converter

- Industrial media converter

- 1-port 10/100/1000T to 1000X SFP

- High Power POE – POE+

- Protection class IP67

- input 24-56VDC

€ 144,00 (ex. VAT)

€ 174,24 (incl. VAT)

Managed Industrial Ethernet Switch

– DC power adapter

– Din-rail mounting suitable

– Power 10Watt

– Output voltage: 24Volt DC

€ 15,86 (ex. VAT)

€ 19,19 (incl. VAT)